|

Exploring Laminate: The Technical Side of Laminate (aka Melamine)

Despite Laminate Doors and Panels being widespread, few people understand exactly what a laminated door or panel actually is, or the different types or applications.

What is a Laminate Door or Panel?

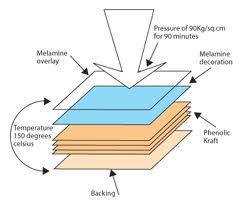

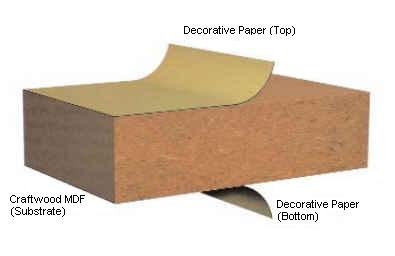

The official definition of laminate is "a man-made decorative material that is applied to the surface of a substrate". It is also commonly known as 'Melamine'. Melamine is a thermally-fused, resin-saturated paper finish (similar to the properties of plastic laminate), and is bonded on both the top and under face of a substrate core. The colour of the laminate is actually a thin layer of coloured (printed) paper being 0.1mm thick. This paper has resins applied to 'seal the colour in' and then the melamine is bonded to the substrate.

Traditionally, a Laminated Door was made from a sheet of High Pressure Laminate (HPL), being 0.4 or 0.8 mm thick, which was glued onto a substrate material using a contact adhesive spray, and then pressed together by the Cabinetmaker. This is still done today with unique colours, however with the advancements in technology, this is now very rare. Most of the laminate colours that you would normally use for Doors and Panels, are available as a pre-finished Laminated board ready to be cut up to the sizes required.

Pre-finished laminated boards are far more economical to buy, as they are mass produced in large automated factories.

Traditional laminated doors use a thicker, high pressure laminate (HPL), which is usually reserved for horizontal applications (like bench tops). The pre-finished melamine laminate doors use a thinner, Low Pressure Laminate (LPL), as Doors and Panels don't require the High Pressure aspect, as they are typically used as a vertical application and are not cut on (unlike bench tops). This makes the melamine laminate much cheaper to produce.

The Low Pressure Laminate coating is sometimes referred to as direct-pressure laminate. They are comprised of a single-wear layer (resin), over a single decorative sheet (printed paper) and are only recommended for vertical surfaces or low-impact areas. This makes them ideal for cabinetry doors and panels. The substrate material is either MR MDF (moisture resistant medium density fibre board) or HMR PB (high moisture resistant particle board) and the sheet size is 16mm thick (standard) or 18mm thick (optional extra).

Whilst the purest would argue that a laminated door is not the same as a melamine door, traditional laminated doors are now so rarely ever done anymore as they are very expensive to do. The fact that most DIY'ers refer to a melamine door as a laminated door (as they don't know the difference), we will do the same.

Laminate is:

- Hard-wearing

- Practical

- Heat and impact-resistant

- Low maintenance

- Finished product (no additional finishing required, like for example painting or varnishing)

- Comes in hundreds of colour possibilities, ranging from solid colours, abstract patterns to printed wood grains

- Easily-cleanable surface

- The most cost effective Door and Panel material available today

- Reliable & stable product

- Been around for years

- Offers high value for the investment outlay

- Is a very popular choice for the budget conscious renovator who also wants a long-life, durable product

History:

The Westinghouse Corporation invented laminate in 1909 to insulate electrical devices. Laminate's decorative use began in the 1920s, using a top layer of decorative paper. Laminated Doors and Panels have been around now for over 50 years.

More Information?:

- To view the different range of laminate colours, click here.

- For a 'fact sheet' on laminate Doors and Panels, click here.

- For care and maintenance information about Laminate Doors and Panels, click here.

Notes:

- A laminated door is moisture resistant, not water proof.

- Laminate is also commonly known in Australia as a 'Laminex door' or a 'Formica door', but these are actually the company trading names of the actual laminate suppliers.

We hope that this information has been helpful for you.

If you need further help or more information on this topic please:

|